ITk Endcap At Nikhef

The construction of the ITk Strip End-caps is done at Nikhef. On this page, you will find the information related to that process.

Author: Andrea García Alonso

Wheel production

Wheel conduction after assembly

Wheel and Blade production documentation & characterisation

Wheel and Blade production documentation & characterisation

Wheel locking point measurements

Wheel locking point measurements

Wheel QA/QC

Inner ring measurements

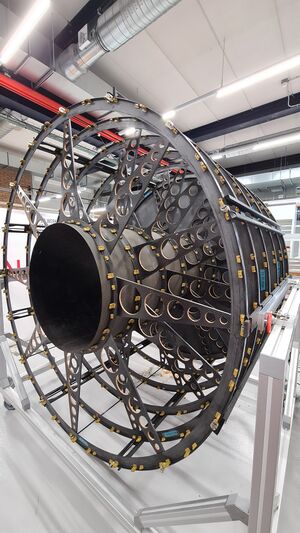

End-cap structure

- Wheel installation

The produced wheels have been installed in the two end-caps as shown in the table. Wheels with Erno number 1 and 14 don't belong to any EC (spare).

| End-cap wheel

position |

Erno

number |

Dutch-shape

number |

|---|---|---|

| End-cap A - Wheel#0 | 11 | 19056-13-A7 |

| End-cap A - Wheel#1 | 2 | 19056-15-B2 |

| End-cap A - Wheel#2 | 9 | 19056-13-A3 |

| End-cap A - Wheel#3 | 13 | 19056-15-b6 |

| End-cap A - Wheel#4 | 7 | 19056-13-A2 |

| End-cap A - Wheel#5 | 12 | 19056-15-B5 |

| End-cap C - Wheel#0 | 6 | 19056-13-A1 |

| End-cap C - Wheel#1 | 4 | 19056-15-B3 |

| End-cap C - Wheel#2 | 10 | 19056-13-A4 |

| End-cap C - Wheel#3 | 5 | 19056-15-B4 |

| End-cap C - Wheel#4 | 8 | 19056-13-A6 |

| End-cap C - Wheel#5 | 3 | 19056-13-A5 |

For EC-A, in the wheel entries in the ITk Production database, there's a set of slides with the results from the measurements of the distance between the wheel rim and the lower petal. The purpose was to check if there's enough space for the RF box. The test was done using the measurement petal, and placing it on the lowest locking points. Each measurement was performed next to a spacer rod. Important to take into account that the locking points closer to the inner cylinder might be a bit shorter than the ones on the wheel rim (sometimes the actual height would be probably 0.5mm smaller than measured).

- Characterization of mechanical behaviour EC structure at cold temperatures

EC structure temperature studies

- Stiffener disk measurements

The stiffening disks of the End-caps, made of Ultem foam with a carbon-fiber face-sheet, were produced and tested at Nikhef. The stiffening disks provide structural stiffness to the EC and act as a thermal barrier. To certify that the three manufactured stiffening disks comply with the specifications, an ATLAS internal note was written to explain the thermal deformation tests carried out at Nikhef, at the end of 2021 and the beginning of 2022. Although it is quite difficult to measure small thermal deformations on such big structures, three tests were performed: temperature changes, local temperature gradients, and global temperature gradients. The results show that the deformations in two disks are consistent with the specifications. The remaining disk is chosen as spare since it deforms above expected, although still mechanically acceptable.

You can find the ATLAS internal note called "Temperature deformation tests of the ITk strip end-cap stiffening disks produced at Nikhef" here: https://cds.cern.ch/record/2824857. In case you don't have access, please contact Andrea García Alonso.

- PP1 patch panel

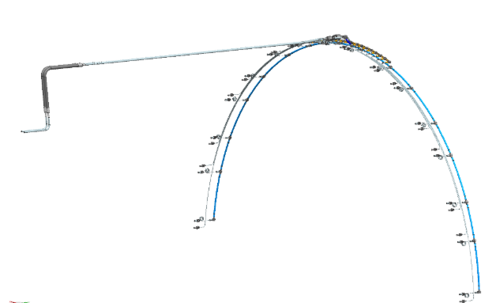

- Cooling manifolds

The ITk strip End-cap detector consists of 6 wheels that each accommodate 32 petals. The petals are cooled with a 2-phase CO2 system using cooling service modules that serve 16 petals, corresponding to half a wheel.

Status on 1st June 2023:

Disk 0 manifolds fabrication is not finished

All manifolds for disk 1 and disk 2 are fabricated, the As and Bs for disk 3 are fabricated as well. Disk 2, outlet manifolds A, B, C and D are cleaned by 31st May 2023.

Summer 2023: Pressure tests + leak tests + alcohol flushing

Every manifold is tested at a high pressure (170 bar) and a check for leaks is performed using Helium. Afterwards, every manifold is internally cleaned with alcohol to assure that no small particles could eventually block the capillarities to which the manifold will be connected.

Test reports and status available here:

| Inlet

manifold |

Produced | Preassure

tested |

Leak

tested |

Alcohol

flushed |

Ready for

installation |

Outlet

manifold |

Produced | Preassure

tested |

Leak

tested |

Alcohol

flushed |

Ready for

installation | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Disk 0 - A | ✓ | YES | Disk 0 - A | ✓ | YES | |||||||

| Disk 0 - B | ✓ | YES | Disk 0 - B | ✓ | YES | |||||||

| Disk 0 - C | ✓ | YES | Disk 0 - C | ✓ | YES | |||||||

| Disk 0 - D | ✓ | YES | Disk 0 - D | ✓ | YES | |||||||

| Disk 1 - A | ✓ | 05/10/23 | 05/10/23 | YES | Disk 1 - A | ✓ | 06/10/23 | 06/10/23 | YES | |||

| Disk 1 - B | ✓ | 26/07/23 | 26/07/23 | 08/09/23 | YES | Disk 1 - B | ✓ | 01/08/23 | 01/08/23 | 03/10/23 | YES | |

| Disk 1 - C | ✓ | 27/07/23 | 27/07/23 | 08/09/23 | YES | Disk 1 - C | ✓ | YES | ||||

| Disk 1 - D | ✓ | 27/07/23 | 27/07/23 | YES | Disk 1 - D | ✓ | 02/08/23 | 02/08/23 | 03/10/23 | YES | ||

| Disk 2 - A | ✓ | 12/07/23 | 13/07/23 | 11/08/23 | YES | Disk 2 - A | ✓ | 28/07/23 | 28/07/23 | 14/09/23 | YES | |

| Disk 2 - B | ✓ | 11/07/23 | 11/07/23 | 11/08/23 | YES | Disk 2 - B | ✓ | 28/07/23 | 28/07/23 | 14/09/23 | YES | |

| Disk 2 - C | ✓ | 13/07/23 | 13/07/23 | 11/08/23 | YES | Disk 2 - C | ✓ | 31/07/23 | 31/07/23 | 20/09/23 | YES | |

| Disk 2 - D | ✓ | 18/07/23 | 19/07/23 | 11/08/23 | YES | Disk 2 - D | ✓ | 31/07/23 | 31/07/23 | 20/09/23 | YES | |

| Disk 3 - A | ✓ | 20/07/23 | 20/07/23 | 31/08/23 | YES | Disk 3 - A | ✓ | 01/08/23 | 01/08/23 | YES | ||

| Disk 3 - B | ✓ | 24/07/23 | 24/07/23 | 31/08/23 | YES | Disk 3 - B | ✓ | 02/08/23 | 02/08/23 | YES | ||

| Disk 3 - C | ✓ | YES | Disk 3 - C | ✓ | YES | |||||||

| Disk 3 - D | ✓ | YES | Disk 3 - D | ✓ | YES | |||||||

| Disk 4 - A | ✓ | 26/07/23 | 26/07/23 | YES | Disk 4 - A | ✓ | YES | |||||

| Disk 4 - B | ✓ | 05/10/23 | 05/10/23 | YES | Disk 4 - B | ✓ | YES | |||||

| Disk 4 - C | ✓ | YES | Disk 4 - C | ✓ | YES | |||||||

| Disk 4 - D | ✓ | YES | Disk 4 - D | ✓ | YES | |||||||

| Disk 5 - A | ✓ | YES | Disk 5 - A | ✓ | 09/10/23 | 09/10/23 | YES | |||||

| Disk 5 - B | ✓ | YES | Disk 5 - B | ✓ | 09/10/23 | 09/10/23 | YES | |||||

| Disk 5 - C | ✓ | YES | Disk 5 - C | ✓ | YES | |||||||

| Disk 5 - D | ✓ | YES | Disk 5 - D | ✓ | YES |

Cleanroom at Nikhef

Miscellaneous documents

- Click here for the request regarding temporary connectors (pdf).

- ITk pictures by Jesse van Dongen

- EC mockup fb2020