Difference between revisions of "ITk Endcap At Nikhef"

(finish the manifolds table) |

(→- Inner ring measurements: - summarise) |

||

| (75 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

| − | ''[https://wiki.nikhef.nl/atlas/ITk_Endcap_Homepage Back to ITk Endcap Homepage]'' | + | <math>\blacktriangleleft</math> ''[https://wiki.nikhef.nl/atlas/ITk_Endcap_Homepage Back to ITk Endcap Homepage]'' |

| + | ----Contents author: Andrea García Alonso (aalonso@nikhef.nl) | ||

| − | The construction of the ITk Strip End-caps | + | The construction of the ITk Strip End-caps at Nikhef. This page contains quality control QC and quality assurance QA tests done over each of the EC structure individual components and the final global structure. |

| − | |||

| − | |||

| − | = | + | [[File:EC1 on 25-05-2023.jpg|thumb|EC1 structure on 25/05/2023|397x397px|alt=|left]] |

| − | === | + | ==Wheels== |

| − | |||

| − | ===Wheel | + | ===- Wheel conduction after assembly=== |

| − | + | By Geoffrey Gilles: | |

| − | + | The conduction of the wheels was tested after their assembly. The main goal of these measurements was to inspect whether the electrical conductivity was properly preserved over the entire wheel structure. The minimum resistance was measured at 3 ring-to-blade connections. | |

| − | |||

| − | + | Results of these measurements available [https://www.nikhef.nl/~ggilles/ITk_QC/index.html here]. | |

| − | [ | ||

| − | === | + | A downloadable spreadsheet version of these results can also be found [https://www.nikhef.nl/pub/experiments/atlas/ITk/data/geoffrey/wheel_production.xlsx here]. |

| − | [ | + | ===- Wheel and Blade production documentation & characterisation=== |

| + | By Erno Roeland: | ||

| + | *[https://www.nikhef.nl/pub/experiments/atlas/ITk/data/Erno/Blades_and_Rims.xlsx Blades_and_Rims.xlsx] | ||

| + | *[https://www.nikhef.nl/pub/experiments/atlas/ITk/data/Erno/Wheel_Production.xlsx Wheel_Production.xlsx] | ||

| + | For an overview of the naming conventions used for the wheels, blades, inner rings and outer rings, click here: [https://www.nikhef.nl/pub/experiments/atlas/ITk/data/Erno/2022_06_01_WheelOverview.xlsx 2022_06_01_WheelOverview.xlsx]. | ||

| + | For the most recent spreadsheet containing the blade and rim production overview and database status, see [https://www.nikhef.nl/pub/experiments/atlas/ITk/data/Erno/2022_05_24_Blades_and_Rims.xlsx 2022_05_24_Blades_and_Rims.xlsx]. | ||

| + | ===- Wheel locking point measurements=== | ||

| + | Information on the positioning of the locking points on each of the wheels available here (nikhef, nikhef): https://www.nikhef.nl/~dyvanar/ITKproject/html/subpages/wheel_lockingpoint_measurements.html | ||

| − | == | + | ===- Wheel QA/QC=== |

| + | The wheel QA/QC document is available [https://www.nikhef.nl/pub/experiments/atlas/ITk/data/marcel/QA_QC%20on%20wheels%20and%20locking%20points_21Mar22.pdf here] (last version, dated 21/03/2022, pdf format). It contains information on a set of QA/QC tests, including petal fit tests and wheel & stiffener disk sag measurements. | ||

| + | |||

| + | ===- Inner ring measurements=== | ||

| + | By Brian Moser: | ||

| + | |||

| + | Contents of the inner ring measurement cernbox: See also the [https://www.nikhef.nl/pub/experiments/atlas/ITk/data/brian/Brian/README README]. The cernbox ([https://cernbox.cern.ch/s/M0JGjSzexPB1Ubm here]) contains a folder on Circularity, Bending, Angle and Width measurements. | ||

| − | + | Inner rim measurement presentation: [https://www.nikhef.nl/pub/experiments/atlas/ITk/data/brian/BrianMoser_InnerRimMeasurements_Updates_31052019.pdf here] and summary presentation: [https://www.nikhef.nl/pub/experiments/atlas/ITk/data/brian/BrianMoser_ITKComparisonPlots_Summary_v0.pdf here]. | |

| − | + | ---- | |

| − | + | ---- | |

| − | + | == Stiffening disk == | |

| − | + | [[File:Stiffener disk thermal deformation tests on 21-01-2022.jpg|thumb|alt=|350x350px|One of the thermal deformation tests on one of the stiffening disks. Picture of 21-01-2022]]The stiffening disks of the End-caps, made of Ultem foam with a carbon-fiber face-sheet, were produced and tested at Nikhef. The stiffening disks provide structural stiffness to the EC and act as a thermal barrier. To certify that the three manufactured stiffening disks comply with the specifications, an ATLAS internal note was written to explain the thermal deformation tests carried out at Nikhef, at the end of 2021 and the beginning of 2022. Although it is quite difficult to measure small thermal deformations on such big structures, three tests were performed: temperature changes, local temperature gradients, and global temperature gradients. The results show that the deformations in two disks are consistent with the specifications. The remaining disk is chosen as spare since it deforms above expected, although still mechanically acceptable. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | | | ||

| − | | | ||

| − | | | ||

| − | | | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | [[File:ATL-COM-ITK-2022-064.pdf|border|center|thumb|ATLAS Note with all the EC stiffening disk QC]] | |

| − | + | You can find the ATLAS internal note called "Temperature deformation tests of the ITk strip end-cap stiffening disks produced at Nikhef" here: https://cds.cern.ch/record/2824857. In case you don't have access, please contact Andrea García Alonso. | |

| − | + | [http://wiki.nikhef.nl/atlas/ITk_Endcap_StiffenerDisk Stiffening Disk] | |

| − | [http://wiki.nikhef.nl/atlas/ITk_Endcap_StiffenerDisk | ||

| − | |||

| − | |||

| − | == | + | ---- |

| + | ---- | ||

| + | == Cooling manifolds == | ||

The ITk strip End-cap detector consists of 6 wheels that each accommodate 32 petals. The petals are cooled with a 2-phase CO2 system using cooling service modules that serve 16 petals, corresponding to half a wheel. | The ITk strip End-cap detector consists of 6 wheels that each accommodate 32 petals. The petals are cooled with a 2-phase CO2 system using cooling service modules that serve 16 petals, corresponding to half a wheel. | ||

| − | [[File:Cooling manifold.png|none|thumb| | + | [[File:Cooling manifold.png|none|thumb|367x367px|Cooling manifold]] |

====== Status on 1st June 2023: ====== | ====== Status on 1st June 2023: ====== | ||

| Line 109: | Line 57: | ||

All manifolds for disk 1 and disk 2 are fabricated, the As and Bs for disk 3 are fabricated as well. Disk 2, outlet manifolds A, B, C and D are cleaned by 31st May 2023. | All manifolds for disk 1 and disk 2 are fabricated, the As and Bs for disk 3 are fabricated as well. Disk 2, outlet manifolds A, B, C and D are cleaned by 31st May 2023. | ||

| − | [[File:Manifolds_status_06-06-2023.jpg|alt=|none|thumb| | + | [[File:Manifolds_status_06-06-2023.jpg|alt=|none|thumb|457x457px|Manifolds production status on 06/06/2023]] |

====== Summer 2023: Pressure tests + leak tests + alcohol flushing ====== | ====== Summer 2023: Pressure tests + leak tests + alcohol flushing ====== | ||

| Line 118: | Line 66: | ||

[https://cernbox.cern.ch/files/spaces/eos/user/m/marcelv/ITK-map/Production/Results/Sub_Assembly/Pressure_test_SA cernbox.cern.ch/files/spaces/eos/user/m/marcelv/ITK-map/Production/Results/Sub_Assembly/Pressure_test_SA] | [https://cernbox.cern.ch/files/spaces/eos/user/m/marcelv/ITK-map/Production/Results/Sub_Assembly/Pressure_test_SA cernbox.cern.ch/files/spaces/eos/user/m/marcelv/ITK-map/Production/Results/Sub_Assembly/Pressure_test_SA] | ||

{| class="wikitable mw-collapsible" | {| class="wikitable mw-collapsible" | ||

| − | |+Status of the inlet and outlet manifolds for EC1 (A-B) and EC2 (C-D) | + | |+ |

| + | Status of the inlet and outlet manifolds for EC1 (A-B) and EC2 (C-D) | ||

!Inlet | !Inlet | ||

manifold | manifold | ||

| Line 480: | Line 429: | ||

|YES | |YES | ||

|} | |} | ||

| + | ---- | ||

| + | ---- | ||

| + | ==PP1 patch panel== | ||

| + | [http://wiki.nikhef.nl/atlas/ITk_Endcap_PP1_PatchPanel PP1 Patch Panel] | ||

| + | |||

| + | '''Plan for QA/QC during 2024''' | ||

| + | |||

| + | - Tcycle a piece between +40, -35 (or reasonably low) in a dry-air or N2 bag. | ||

| + | |||

| + | - Measure ohmic R with voltmeter on ~10 places randomly. | ||

| + | |||

| + | - Measure R between all inserts and surface. R<10 Ohm, otherwise we probably need to fix. (or are all inserts grounded anyway via their bolts). | ||

| + | ---- | ||

| + | ---- | ||

| + | ==End-cap structure== | ||

| + | |||

| + | === - Wheel and manifold installation - Positions on ECs and numbering === | ||

| + | The produced wheels have been installed in the two end-caps as shown in the table. "EC wheel position" refers to the physical level on the EC, where 0 is the top (closest to Interaction Point IP) and 5 is the bottom (furthest from IP). "Erno number" is the identifier that was given at Nikhef to individual wheels. "Dutch-shape number" is the identifier given by the company that milled the locking points. Wheels with Erno number 1 and 14 don't belong to any EC (spare). | ||

| + | |||

| + | The inlet and outlet cooling manifolds are installed in the EC and are referred on the 4th column of the table. The pair inlet-outlet is matched according to their numbers, a.k.a. ''inlet manifold 1A'' and ''outlet manifold 1A'' are placed together, with their VCR connectors at the same location. Cooling manifolds installed close to the beam that has a corner pointing to the right (when EC standing on BH) are identified in the table as "@R beam", while those manifolds close to the beam with the corner pointing left are labeled "@L beam". Manifolds on wheel #0 will be taken away for transport to DESY, so they will have to install them again and if they follow the pattern of the rest of manifolds they will place them so all the As are together and all the Bs as well (not as it is at the moment, June 2024). | ||

| + | [[File:Final EC-A with Beam Left.png|thumb|428x428px|Final EC-A with Left Beam marked with arrow]] | ||

| + | {| class="wikitable" | ||

| + | ! rowspan="2" |End-cap wheel | ||

| + | position | ||

| + | ! rowspan="2" |Erno | ||

| + | number | ||

| + | ! rowspan="2" |Dutch-shape | ||

| + | number | ||

| + | ! colspan="2" |Cooling manifolds | ||

| + | |- | ||

| + | !@R beam | ||

| + | !@L beam | ||

| + | |- | ||

| + | |End-cap A - Wheel#0 | ||

| + | |11 | ||

| + | |19056-13-A7 | ||

| + | |0A | ||

| + | |0B | ||

| + | |- | ||

| + | |End-cap A - Wheel#1 | ||

| + | |2 | ||

| + | |19056-15-B2 | ||

| + | |1B | ||

| + | |1A | ||

| + | |- | ||

| + | |End-cap A - Wheel#2 | ||

| + | |9 | ||

| + | |19056-13-A3 | ||

| + | |2B | ||

| + | |2A | ||

| + | |- | ||

| + | |End-cap A - Wheel#3 | ||

| + | |13 | ||

| + | |19056-15-b6 | ||

| + | |3B | ||

| + | |3A | ||

| + | |- | ||

| + | |End-cap A - Wheel#4 | ||

| + | |7 | ||

| + | |19056-13-A2 | ||

| + | |4B | ||

| + | |4A | ||

| + | |- | ||

| + | |End-cap A - Wheel#5 | ||

| + | |12 | ||

| + | |19056-15-B5 | ||

| + | |5B | ||

| + | |5A | ||

| + | |- | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | |- | ||

| + | |End-cap C - Wheel#0 | ||

| + | |6 | ||

| + | |19056-13-A1 | ||

| + | | | ||

| + | | | ||

| + | |- | ||

| + | |End-cap C - Wheel#1 | ||

| + | |4 | ||

| + | |19056-15-B3 | ||

| + | | | ||

| + | | | ||

| + | |- | ||

| + | |End-cap C - Wheel#2 | ||

| + | |10 | ||

| + | |19056-13-A4 | ||

| + | | | ||

| + | | | ||

| + | |- | ||

| + | |End-cap C - Wheel#3 | ||

| + | |5 | ||

| + | |19056-15-B4 | ||

| + | | | ||

| + | | | ||

| + | |- | ||

| + | |End-cap C - Wheel#4 | ||

| + | |8 | ||

| + | |19056-13-A6 | ||

| + | | | ||

| + | | | ||

| + | |- | ||

| + | |End-cap C - Wheel#5 | ||

| + | |3 | ||

| + | |19056-13-A5 | ||

| + | | | ||

| + | | | ||

| + | |} | ||

| + | |||

| + | === - Wheel installation - Distances between wheel rim and lower petals === | ||

| + | |||

| + | One of the QC tests in a full EC structure consists on checking the actual distances that the locking points leave between the petals and the wheel rims. | ||

| + | |||

| + | |||

| + | |||

| + | [[File:EC-A with Test petal.png|left|frameless|470x470px|EC-A with Test petal]] | ||

| + | |||

| + | [[File:Lower petal-wheel rim distance EC-A.pdf|alt=Lower petal-wheel rim distance EC-A|center|frameless|Lower petal-wheel rim distance EC-A]] | ||

| + | |||

| + | For EC-A, these are the results from the measurements of the '''distance between the wheel rim and the lower petal'''. They are also available in the [https://itkpd-test.unicorncollege.cz/componentView?code=9c7745de9896b5c95f7ccaf804e6730e wheel entries in the ITk Production database]. The purpose was to check if there's enough space for the RF box. The test was done using the measurement petal, and placing it on the lowest locking points. Each measurement was performed next to a spacer rod. Important to take into account that the locking points closer to the inner cylinder might be a bit shorter than the ones on the wheel rim (sometimes the actual height would be probably 0.5mm smaller than measured). | ||

| + | |||

| + | |||

| + | |||

| + | [[File:Lower petal-wheel rim distance EC-C.pdf|thumb|alt=]] | ||

| + | |||

| + | Due to sensor cracking, one of the potential case scenarios is that the petals will get an extra layer of material, resulting in a larger petal thickness. This could be problematic if there is not enough space between the lower petals and the wheel rims in the already built EC structures (A and C). EC-A was already measured when the RF box issue was addressed, but now EC-C as well. | ||

| + | |||

| + | [[File:ECs deviations 7mm distance lowerPetal wheelRim.png|thumb|alt=|none|732x732px]] | ||

| + | |||

| + | === - EC geometric measurement - Stiffness === | ||

| + | A load of a hundred kilograms was placed inside the EC inner cylinder to mimic the operational conditions. Several 3D laser measurements indicated that the EC structures have a high stiffness leading to only 20 to 60 µm effects when loaded. | ||

| + | |||

| + | Test summary presented in the ITk week March 2024: https://indico.cern.ch/event/1353986/contributions/5865828/attachments/2822702/4929833/EC%20GEOMETRIC%20MEASUREMENT%20-%20ATLAS%20ITk%20Week%20180324.pdf | ||

| + | |||

| + | ===- Characterization of mechanical behaviour EC structure at cold temperatures=== | ||

| + | [http://wiki.nikhef.nl/atlas/ITk_Endcap_Structure_TemperatureStudies EC structure temperature studies] | ||

| + | ---- | ||

| + | ---- | ||

| + | |||

| + | == Other EC structure related topics == | ||

| + | |||

| + | === Petal test box === | ||

| − | ==Cleanroom at Nikhef== | + | ===Cleanroom at Nikhef=== |

| − | [ | + | Click [https://www.nikhef.nl/pub/experiments/atlas/ITk/data/marcel/NikhefInfra/ITk%20doc%20for%20Nikhef%20cleanroom.pdf here] for the Nikhef cleanroom document (pdf). |

| − | == Miscellaneous documents == | + | === Miscellaneous documents === |

* Click [https://www.nikhef.nl/pub/experiments/atlas/ITk/data/marcel/TempConnectors/temporary%20connectors.pdf here] for the request regarding temporary connectors (pdf). | * Click [https://www.nikhef.nl/pub/experiments/atlas/ITk/data/marcel/TempConnectors/temporary%20connectors.pdf here] for the request regarding temporary connectors (pdf). | ||

* [https://surfdrive.surf.nl/files/index.php/s/Hb5lxIQ95zAJPdo ITk pictures by Jesse van Dongen] | * [https://surfdrive.surf.nl/files/index.php/s/Hb5lxIQ95zAJPdo ITk pictures by Jesse van Dongen] | ||

* [https://surfdrive.surf.nl/files/index.php/s/fkwsPtIgcjkLSB4 EC mockup fb2020] | * [https://surfdrive.surf.nl/files/index.php/s/fkwsPtIgcjkLSB4 EC mockup fb2020] | ||

Latest revision as of 12:21, 13 January 2025

Contents author: Andrea García Alonso (aalonso@nikhef.nl)

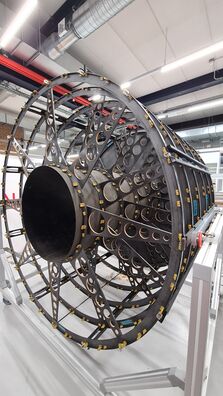

The construction of the ITk Strip End-caps at Nikhef. This page contains quality control QC and quality assurance QA tests done over each of the EC structure individual components and the final global structure.

Wheels

- Wheel conduction after assembly

By Geoffrey Gilles:

The conduction of the wheels was tested after their assembly. The main goal of these measurements was to inspect whether the electrical conductivity was properly preserved over the entire wheel structure. The minimum resistance was measured at 3 ring-to-blade connections.

Results of these measurements available here.

A downloadable spreadsheet version of these results can also be found here.

- Wheel and Blade production documentation & characterisation

By Erno Roeland:

For an overview of the naming conventions used for the wheels, blades, inner rings and outer rings, click here: 2022_06_01_WheelOverview.xlsx.

For the most recent spreadsheet containing the blade and rim production overview and database status, see 2022_05_24_Blades_and_Rims.xlsx.

- Wheel locking point measurements

Information on the positioning of the locking points on each of the wheels available here (nikhef, nikhef): https://www.nikhef.nl/~dyvanar/ITKproject/html/subpages/wheel_lockingpoint_measurements.html

- Wheel QA/QC

The wheel QA/QC document is available here (last version, dated 21/03/2022, pdf format). It contains information on a set of QA/QC tests, including petal fit tests and wheel & stiffener disk sag measurements.

- Inner ring measurements

By Brian Moser:

Contents of the inner ring measurement cernbox: See also the README. The cernbox (here) contains a folder on Circularity, Bending, Angle and Width measurements.

Inner rim measurement presentation: here and summary presentation: here.

Stiffening disk

The stiffening disks of the End-caps, made of Ultem foam with a carbon-fiber face-sheet, were produced and tested at Nikhef. The stiffening disks provide structural stiffness to the EC and act as a thermal barrier. To certify that the three manufactured stiffening disks comply with the specifications, an ATLAS internal note was written to explain the thermal deformation tests carried out at Nikhef, at the end of 2021 and the beginning of 2022. Although it is quite difficult to measure small thermal deformations on such big structures, three tests were performed: temperature changes, local temperature gradients, and global temperature gradients. The results show that the deformations in two disks are consistent with the specifications. The remaining disk is chosen as spare since it deforms above expected, although still mechanically acceptable.

File:ATL-COM-ITK-2022-064.pdf

You can find the ATLAS internal note called "Temperature deformation tests of the ITk strip end-cap stiffening disks produced at Nikhef" here: https://cds.cern.ch/record/2824857. In case you don't have access, please contact Andrea García Alonso.

Cooling manifolds

The ITk strip End-cap detector consists of 6 wheels that each accommodate 32 petals. The petals are cooled with a 2-phase CO2 system using cooling service modules that serve 16 petals, corresponding to half a wheel.

Status on 1st June 2023:

Disk 0 manifolds fabrication is not finished

All manifolds for disk 1 and disk 2 are fabricated, the As and Bs for disk 3 are fabricated as well. Disk 2, outlet manifolds A, B, C and D are cleaned by 31st May 2023.

Summer 2023: Pressure tests + leak tests + alcohol flushing

Every manifold is tested at a high pressure (170 bar) and a check for leaks is performed using Helium. Afterwards, every manifold is internally cleaned with alcohol to assure that no small particles could eventually block the capillarities to which the manifold will be connected.

Test reports and status available here:

| Inlet

manifold |

Produced | Preassure

tested |

Leak

tested |

Alcohol

flushed |

Ready for

installation |

Outlet

manifold |

Produced | Preassure

tested |

Leak

tested |

Alcohol

flushed |

Ready for

installation | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Disk 0 - A | ✓ | ✓ | ✓ | ✓ | YES | Disk 0 - A | ✓ | ✓ | ✓ | ✓ | YES | |

| Disk 0 - B | ✓ | ✓ | ✓ | ✓ | YES | Disk 0 - B | ✓ | ✓ | ✓ | ✓ | YES | |

| Disk 0 - C | ✓ | ✓ | ✓ | ✓ | YES | Disk 0 - C | ✓ | ✓ | ✓ | ✓ | YES | |

| Disk 0 - D | ✓ | ✓ | ✓ | ✓ | YES | Disk 0 - D | ✓ | ✓ | ✓ | ✓ | YES | |

| Disk 1 - A | ✓ | ✓ | ✓ | ✓ | YES | Disk 1 - A | ✓ | ✓ | ✓ | ✓ | YES | |

| Disk 1 - B | ✓ | ✓ | ✓ | ✓ | YES | Disk 1 - B | ✓ | ✓ | ✓ | ✓ | YES | |

| Disk 1 - C | ✓ | ✓ | ✓ | ✓ | YES | Disk 1 - C | ✓ | ✓ | ✓ | ✓ | YES | |

| Disk 1 - D | ✓ | ✓ | ✓ | ✓ | YES | Disk 1 - D | ✓ | ✓ | ✓ | ✓ | YES | |

| Disk 2 - A | ✓ | ✓ | ✓ | ✓ | YES | Disk 2 - A | ✓ | ✓ | ✓ | ✓ | YES | |

| Disk 2 - B | ✓ | ✓ | ✓ | ✓ | YES | Disk 2 - B | ✓ | ✓ | ✓ | ✓ | YES | |

| Disk 2 - C | ✓ | ✓ | ✓ | ✓ | YES | Disk 2 - C | ✓ | ✓ | ✓ | ✓ | YES | |

| Disk 2 - D | ✓ | ✓ | ✓ | ✓ | YES | Disk 2 - D | ✓ | ✓ | ✓ | ✓ | YES | |

| Disk 3 - A | ✓ | ✓ | ✓ | ✓ | YES | Disk 3 - A | ✓ | ✓ | ✓ | ✓ | YES | |

| Disk 3 - B | ✓ | ✓ | ✓ | ✓ | YES | Disk 3 - B | ✓ | ✓ | ✓ | ✓ | YES | |

| Disk 3 - C | ✓ | ✓ | ✓ | ✓ | YES | Disk 3 - C | ✓ | ✓ | ✓ | ✓ | YES | |

| Disk 3 - D | ✓ | ✓ | ✓ | ✓ | YES | Disk 3 - D | ✓ | ✓ | ✓ | ✓ | YES | |

| Disk 4 - A | ✓ | ✓ | ✓ | ✓ | YES | Disk 4 - A | ✓ | ✓ | ✓ | ✓ | YES | |

| Disk 4 - B | ✓ | ✓ | ✓ | ✓ | YES | Disk 4 - B | ✓ | ✓ | ✓ | ✓ | YES | |

| Disk 4 - C | ✓ | ✓ | ✓ | ✓ | YES | Disk 4 - C | ✓ | ✓ | ✓ | ✓ | YES | |

| Disk 4 - D | ✓ | ✓ | ✓ | ✓ | YES | Disk 4 - D | ✓ | ✓ | ✓ | ✓ | YES | |

| Disk 5 - A | ✓ | ✓ | ✓ | ✓ | YES | Disk 5 - A | ✓ | ✓ | ✓ | ✓ | YES | |

| Disk 5 - B | ✓ | ✓ | ✓ | ✓ | YES | Disk 5 - B | ✓ | ✓ | ✓ | ✓ | YES | |

| Disk 5 - C | ✓ | ✓ | ✓ | ✓ | YES | Disk 5 - C | ✓ | ✓ | ✓ | ✓ | YES | |

| Disk 5 - D | ✓ | ✓ | ✓ | ✓ | YES | Disk 5 - D | ✓ | ✓ | ✓ | ✓ | YES |

PP1 patch panel

Plan for QA/QC during 2024

- Tcycle a piece between +40, -35 (or reasonably low) in a dry-air or N2 bag.

- Measure ohmic R with voltmeter on ~10 places randomly.

- Measure R between all inserts and surface. R<10 Ohm, otherwise we probably need to fix. (or are all inserts grounded anyway via their bolts).

End-cap structure

- Wheel and manifold installation - Positions on ECs and numbering

The produced wheels have been installed in the two end-caps as shown in the table. "EC wheel position" refers to the physical level on the EC, where 0 is the top (closest to Interaction Point IP) and 5 is the bottom (furthest from IP). "Erno number" is the identifier that was given at Nikhef to individual wheels. "Dutch-shape number" is the identifier given by the company that milled the locking points. Wheels with Erno number 1 and 14 don't belong to any EC (spare).

The inlet and outlet cooling manifolds are installed in the EC and are referred on the 4th column of the table. The pair inlet-outlet is matched according to their numbers, a.k.a. inlet manifold 1A and outlet manifold 1A are placed together, with their VCR connectors at the same location. Cooling manifolds installed close to the beam that has a corner pointing to the right (when EC standing on BH) are identified in the table as "@R beam", while those manifolds close to the beam with the corner pointing left are labeled "@L beam". Manifolds on wheel #0 will be taken away for transport to DESY, so they will have to install them again and if they follow the pattern of the rest of manifolds they will place them so all the As are together and all the Bs as well (not as it is at the moment, June 2024).

| End-cap wheel

position |

Erno

number |

Dutch-shape

number |

Cooling manifolds | |

|---|---|---|---|---|

| @R beam | @L beam | |||

| End-cap A - Wheel#0 | 11 | 19056-13-A7 | 0A | 0B |

| End-cap A - Wheel#1 | 2 | 19056-15-B2 | 1B | 1A |

| End-cap A - Wheel#2 | 9 | 19056-13-A3 | 2B | 2A |

| End-cap A - Wheel#3 | 13 | 19056-15-b6 | 3B | 3A |

| End-cap A - Wheel#4 | 7 | 19056-13-A2 | 4B | 4A |

| End-cap A - Wheel#5 | 12 | 19056-15-B5 | 5B | 5A |

| End-cap C - Wheel#0 | 6 | 19056-13-A1 | ||

| End-cap C - Wheel#1 | 4 | 19056-15-B3 | ||

| End-cap C - Wheel#2 | 10 | 19056-13-A4 | ||

| End-cap C - Wheel#3 | 5 | 19056-15-B4 | ||

| End-cap C - Wheel#4 | 8 | 19056-13-A6 | ||

| End-cap C - Wheel#5 | 3 | 19056-13-A5 | ||

- Wheel installation - Distances between wheel rim and lower petals

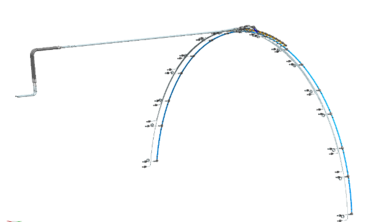

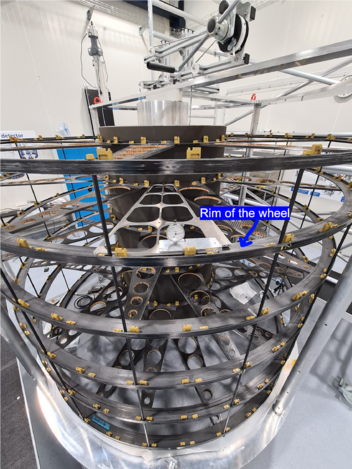

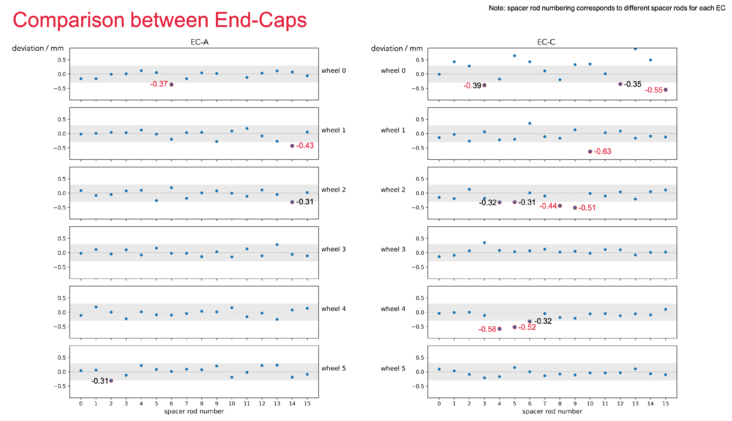

One of the QC tests in a full EC structure consists on checking the actual distances that the locking points leave between the petals and the wheel rims.

File:Lower petal-wheel rim distance EC-A.pdf

For EC-A, these are the results from the measurements of the distance between the wheel rim and the lower petal. They are also available in the wheel entries in the ITk Production database. The purpose was to check if there's enough space for the RF box. The test was done using the measurement petal, and placing it on the lowest locking points. Each measurement was performed next to a spacer rod. Important to take into account that the locking points closer to the inner cylinder might be a bit shorter than the ones on the wheel rim (sometimes the actual height would be probably 0.5mm smaller than measured).

File:Lower petal-wheel rim distance EC-C.pdf

Due to sensor cracking, one of the potential case scenarios is that the petals will get an extra layer of material, resulting in a larger petal thickness. This could be problematic if there is not enough space between the lower petals and the wheel rims in the already built EC structures (A and C). EC-A was already measured when the RF box issue was addressed, but now EC-C as well.

- EC geometric measurement - Stiffness

A load of a hundred kilograms was placed inside the EC inner cylinder to mimic the operational conditions. Several 3D laser measurements indicated that the EC structures have a high stiffness leading to only 20 to 60 µm effects when loaded.

Test summary presented in the ITk week March 2024: https://indico.cern.ch/event/1353986/contributions/5865828/attachments/2822702/4929833/EC%20GEOMETRIC%20MEASUREMENT%20-%20ATLAS%20ITk%20Week%20180324.pdf

- Characterization of mechanical behaviour EC structure at cold temperatures

EC structure temperature studies

Petal test box

Cleanroom at Nikhef

Click here for the Nikhef cleanroom document (pdf).

Miscellaneous documents

- Click here for the request regarding temporary connectors (pdf).

- ITk pictures by Jesse van Dongen

- EC mockup fb2020